本文转自《Design News》发布的题为“Norway Is Opening for Business in Carbon Capture”的报道。

作者:RP Siegel

日期:2018.08.09

原文链接:https://www.designnews.com/materials-assembly/norway-opening-business-carbon-capture/174448485959225

Norway could be getting into the business of importing and sequestering CO2 as a service, thanks to a new undersea project for carbon capture and storage.

由于新的海底碳捕获和储存项目,挪威可能会涉足二氧化碳的进口和封存业务。

The Norwegian Ministry of Petroleum and Energy has announced that it will be moving forward with an undersea project for carbon capture and storage (CSS), the first in the world to be able to store carbon dioxide (CO2) waste from multiple industrial sources. If the project is successful, it will serve as a stepping stone for full scale international operations.

挪威石油和能源部宣布将推进碳捕集与封存海底项目(CSS),这是世界上第一个能够储存多种工业来源的二氧化碳(CO2)废物的项目。 如果项目成功,它将成为全面国际业务的垫脚石。

The impetus behind this is to get ahead of the carbon capture curve and create an economically viable value chain solution for CCS. When this infrastructure is put into place, Norway will be able to import CO2 for permanent storage, providing a ready mechanism for countries and companies to set up their own CCS operations. It will also lower the threshold for a European hydrogen market. Norway could be getting into the business of importing and sequestering CO2 as a service.

这背后的动力是超越碳捕获曲线,为CCS创造经济可行的价值链解决方案。 当这个基础设施建成后,挪威将能够进口二氧化碳用于永久储存,为各国和公司建立自己的CCS业务提供了一个现成的机制。 它还将降低欧洲氢气市场的门槛。 挪威可能正在开展进口和封存二氧化碳作为服务的业务。

The country is already the world leader in carbon storage, going back to the Sleipner Project, which has stored one million tons of CO2 per year since it began about 20 years ago. It was the first facility dedicated to CO2 storage and was installed as a means of avoiding the Norwegian carbon tax and reducing the CO2 content of natural gas produced in the area, which exceeded the specified European Union limit in CO2 concentration of 2.5%.

该国已经是世界碳储存的领导者,回到Sleipner项目,该项目自20年前开始以来每年储存100万吨二氧化碳。 它是第一个专门用于二氧化碳封存的设施,它的设立是为了避免挪威碳税和减少该地区生产的天然气的二氧化碳含量,超过了欧盟规定的二氧化碳浓度2.5%的限制。

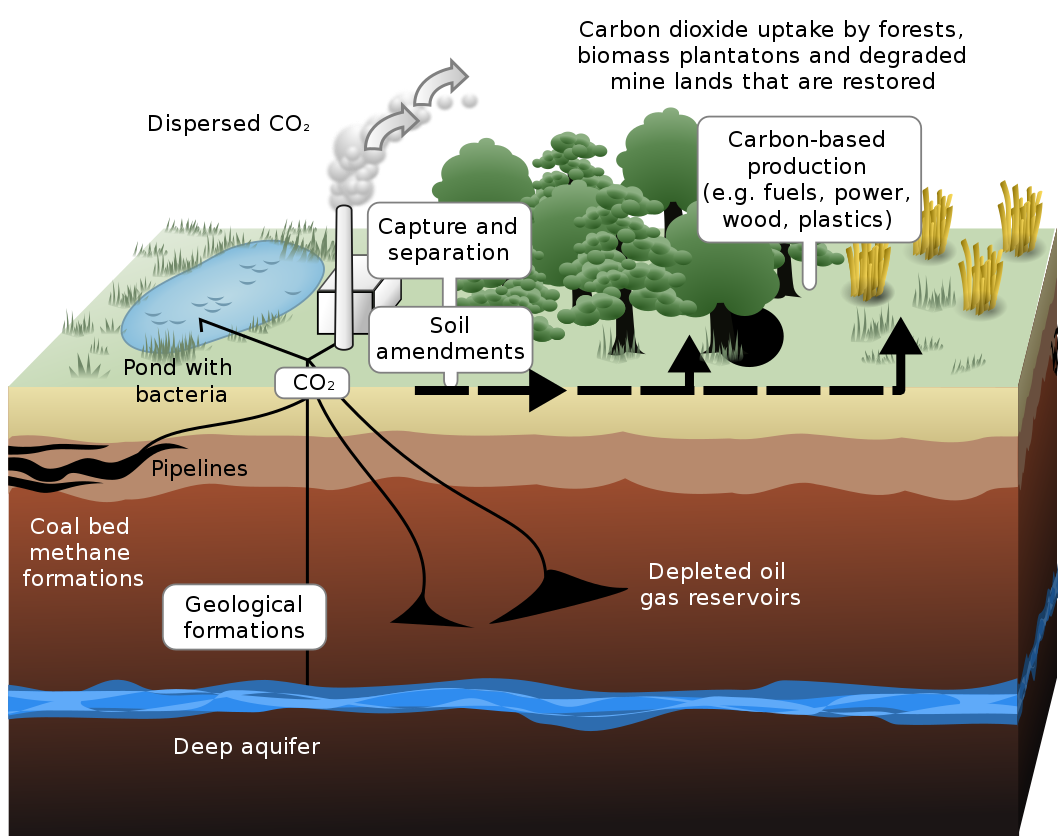

This schematic shows terrestrial and geological sequestration of carbon dioxide emissions from a coal-fired plant.

(Image source: LeJean Hardin and Jamie Paynederivative work: Jarl Arntzen [CC BY-SA 3.0 (https://creativecommons.org/licenses/by-sa/3.0)], via Wikimedia Commons)

该示意图显示了燃煤电厂二氧化碳排放的陆地和地质封存。

(图片来源:LeJean Hardin和Jamie Paynederivative作品:Jarl Arntzen [CC BY-SA 3.0(https://creativecommons.org/licenses/by-sa/3.0)],来自Wikimedia Commons)

The CO2 was removed using an amine-based sorbent, with the excess being pumped under the seabed to a depth of roughly 1 km. Of the 17 large-scale CCS facilities operating worldwide today, only four are dedicated to carbon storage. Two are in Norway (Sleipner and Snøhvit), one in Canada (Quest), and one in the US (Decatur). The rest are being used for enhanced oil recovery.

二氧化碳是用胺基吸附剂去除的,多余的二氧化碳被泵入海床下约1千米的深度。在目前全世界运行的17个大型CCS设施中,只有4个专门用于碳储存。两个在挪威(Sleipner和Snøhvit),一个在加拿大(Quest),一个在美国(Decatur)。其余的用于提高石油采收率。

The importance of CCS technology is hard to overstate, at least for as long as fossil fuels are part of the energy and industrial landscape. The International Energy Agency (IEA) has called CCS a key technology for reducing coal and gas emissions across industries. In a statement to Business Insider, an IEA spokesperson said, “There is no other technology solution [today] that can significantly reduce emissions from the coal and gas power generation capacity that will remain a feature of the electricity mix for the foreseeable future. No other technology solution is capable of delivering the deep emissions reductions needed across key industrial processes, such as steel, cement, and chemicals manufacturing, all of which will remain vital building blocks of modern society.”

CCS技术的重要性很难夸大,至少只要化石燃料是能源和工业领域的一部分。国际能源署(IEA)称CCS是减少各行业煤炭和天然气排放的关键技术。国际能源署发言人在向Business Insider发表的一份声明中表示,“在可预见的未来,煤炭和天然气发电产能的排放仍将是能源结构的一个特征,(目前)没有其他技术方案能够显著降低这一排放。没有任何其他技术解决方案能够提供关键工业流程所需的深度减排,例如钢铁,水泥和化学品制造,所有这些都将成为现代社会的重要组成部分。”

This latest demonstration scale project, which is expected to be online by 2020, is unique in that it will capture emission from two different industry types: a cement factory in Brevik, owned by Heidelberg Cement, and an energy recovery (waste incineration) plant in Oslo. These sites all delivered their concept studies for CO2 capture in the fall of 2017. Each plant plans to capture roughly 400,000 tons annually.

这个最新的示范规模项目预计将于2020年上线,其独特之处在于它将捕获两种不同行业类型的排放:位于Brevik的Heidelberg水泥公司的水泥厂和位于Oslo的一家能源回收(废物焚烧)工厂。 这些地点都在2017年秋季进行了二氧化碳捕集概念研究。每个工厂计划每年捕获大约40万吨。

In operation, CO2 will be transported by ship from each capture plant to an onshore facility on the Norwegian West Coast for temporary storage. It will then be transported via a pipeline to a subsea formation in the North Sea for long-term storage. The Norwegian Ministry of Petroleum and Energy has identified several injection wells east of the Troll field on the Norwegian Continental Shelf. The CO2 will be stored permanently up to 2,000 meters below the seabed.

在运行中,二氧化碳将通过船舶从每个捕集工厂运输到挪威西海岸的陆上设施进行临时存储。 然后通过管道将其运输到北海的海底地层进行长期储存。 挪威石油和能源部已在挪威大陆架的Troll油田以东确定了几口注水井。 二氧化碳将永久储存在海床下方2,000米处。

According to Equinor, an oil and gas company that is a partner in the project and was involved in the earlier Norwegian CCS projects, “The reservoir surveyed for CO2 storage has the capacity to accommodate significant additional volumes.”

Equinor是一家石油和天然气公司,该公司是该项目的合作伙伴,参与了早期的挪威CCS项目,“对进行二氧化碳封存的油藏进行调查,说明其有能力容纳大量的额外容积。”

The company will be responsible for the planning of the storage facility and is also looking into the feasibility of pairing this carbon capture capability with hydrogen production. When hydrogen is produced from natural gas, it emits CO2 as a byproduct. But if the CO2 could be safely sequestered, it could provide a carbon-free alternative. Equinor, along with partners Vattenfall and Gasunie, is currently assessing the possibility of converting a natural gas power plant to run on hydrogen and sequestering the resulting CO2 emissions beneath the seabed.

该公司将负责储存设施的规划,并正在研究将碳捕获能力与氢气生产相结合的可行性。 当氢气由天然气产生时,它会释放出二氧化碳作为副产品。 但如果可以安全地隔离二氧化碳,它可以提供无碳替代品。 Equinor与合作伙伴Vattenfall和Gasunie目前正在评估将天然气发电厂转换为氢气并隔离海床下产生的二氧化碳排放的可能性。

作者简介:RP Siegel, PE, has a master's degree in mechanical engineering and worked for 20 years in R&D at Xerox Corp. An inventor with 50 patents, and now a full-time writer, RP finds his primary interest at the intersection of technology and society. His work has appeared in multiple consumer and industry outlets, and he also co-authored the eco-thriller Vapor Trails.