本文转自《McKinsey&Company》发表的题为“How industry can move toward a low-carbon future”的报道。

日期:2018.07

作者:Arnout de Pee, Dickon Pinner, Occo Roelofsen, Ken Somers, Eveline Speelman, and Maaike Witteveen

原文链接:https://www.mckinsey.com/business-functions/sustainability-and-resource-productivity/our-insights/how-industry-can-move-toward-a-low-carbon-future?cid=soc-web

Cutting industry’s carbon emissions will require significant investment and coordinated effort among businesses, governments, and other stakeholders.

削减工业行业的碳排放将需要企业、政府和其他利益相关者之间的大量投资和协调努力。

The industrial sector is a vital source of wealth, prosperity, and social value on a global scale. Industrial companies produce about one-quarter of global GDP and employment, and they make products and materials that are integral to our daily lives. Their activities, like those of most businesses, also take a toll on the environment. Roughly 28 percent of global greenhouse-gas (GHG) emissions came from industry in 2014. Unless industry can lower its emissions, the world will struggle to reach the GHG reduction targets of 80 to 95 percent that governments set under the Paris Agreement of 2015.

工业部门是全球范围内富裕、繁荣和社会价值的重要来源。 工业公司生产约全球GDP和就业的四分之一,他们生产的产品和材料是我们日常生活中不可或缺的一部分。 与大多数企业一样,他们的活动也会对环境产生影响。 2014年全球大约28%的温室气体(GHG)排放来自工业。除非工业能够降低排放量,否则全球将难以达到政府根据2015年“巴黎协定”制定的80%至95%的温室气体减排目标。

Lowering industrial GHG emissions won’t be easy, but it is possible. A new report from McKinsey, Decarbonization of industrial sectors: The next frontier (PDF–21MB), finds that ammonia, cement, ethylene, and steel companies can reduce their carbon-dioxide (CO2) emissions to almost zero with energy-efficiency improvements, the electric production of heat, the use of hydrogen and biomass as feedstock or fuel, and carbon capture. The decarbonization of these sectors will cost between $11 trillion and $21 trillion through 2050 and will require accelerating the build-out of renewable-energy capacity, to provide four to nine times as much clean power as industry would need in the absence of any effort to reduce emissions.

降低工业温室气体排放并非易事,但这是可能的。 McKinsey的一份新报告提到,工业部门脱碳:下一个边界(PDF-21MB),发现氨,水泥,乙烯和钢铁公司可以通过提高能效来减少二氧化碳(CO2)排放, 电力生产的热量,氢气和生物质的使用作为原料或燃料,以及碳捕获。 到2050年,这些行业的脱碳成本将控制在11万亿美元到21万亿美元之间,并且需要加快可再生能源产能的建设,在没有任何努力的情况下提供4到9倍的清洁能源。 减少排放。

The challenges to reducing industrial CO2 emissions

减少工业二氧化碳排放的挑战

The vast majority of industry’s GHG emissions, 90 percent, consists of CO2. Half of industry’s CO2 emissions result from the manufacture of the four industrial commodities—ammonia, cement, ethylene, and steel—that are the focus of our report.

绝大多数工业的温室气体排放量(90%)由二氧化碳组成。 工业二氧化碳排放量的一半来自四大工业商品的生产 - 氨,水泥,乙烯和钢 - 这是我们报告的重点。

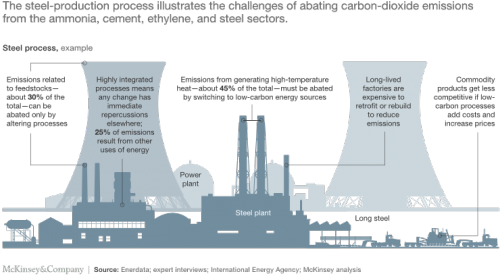

Abating CO2 emissions in the focus sectors is more difficult than it is in most others for four technical reasons (Exhibit 1). First, the 45 percent of CO2 emissions from these sectors that result from feedstocks cannot be abated by a change in fuels, future only by changes to processes. Second, 35 percent of emissions from these sectors come from burning fossil fuels to generate high-temperature heat (in the focus sectors, process temperatures can reach 700 degrees Celsius to more than 1,600 degrees Celsius). Reducing these emissions by switching to alternative fuels, such as zero-carbon electricity, would be difficult because this would require significant changes to the design of furnaces. Third, industrial processes are highly integrated, so any change to one part of a process must be accompanied by changes to other parts of that process. Finally, production facilities have long lifetimes, typically exceeding 50 years with regular maintenance. Changing processes at existing sites requires costly rebuilds or retrofits.

由于四个技术原因,减少重点行业的二氧化碳排放比大多数其他行业更加困难(图1)。首先,原料产生的这些部门的二氧化碳排放量的45%不能通过燃料的变化来减少,未来只能通过改变过程来减少。其次,来自这些行业的35%的排放来自燃烧化石燃料以产生高温热量(在重点领域,工艺温度可以达到700摄氏度到超过1600摄氏度)。通过改用替代燃料(例如零碳电力)来减少这些排放将是困难的,因为这将需要对炉子的设计进行重大改变。第三,工业过程高度集成,因此对过程的一个部分的任何改变必须伴随着对该过程的其他部分的改变。最后,生产设施的使用寿命很长,通常超过50年,并定期进行维护。在现有站点更改流程需要进行昂贵的重建或改造。

Exhibit 1

Economic factors add to the challenge of abating emissions. Ammonia, cement, ethylene, and steel are commodities, so cost is the decisive consideration in purchase decisions. Companies that increase their costs by adopting low-emission processes and technologies will find themselves at a price disadvantage to rivals that do not.

经济因素增加了减排的挑战。 氨,水泥,乙烯和钢是商品,因此成本是购买决策中的决定性因素。 采用低排放工艺和技术来增加成本的公司会发现自己处于价格劣势,而竞争对手却没有这样做。

Options for industrial decarbonization

工业脱碳的选择

Despite the challenges described above, companies in the four focus sectors could bring their CO2 emissions close to zero with a combination of approaches. The most promising are energy-efficiency improvements, the electrification of heat, the use of hydrogen made with zero-carbon electricity as a feedstock or fuel, the use of biomass as a feedstock or fuel, and carbon capture and storage (CCS) or usage (CCU). The optimum mix of decarbonization options will vary from facility to facility, even within the same sector, because local factors determine which ones are most practical or economical. Companies must evaluate their options on a site-specific basis by closely examining these factors.

尽管存在上述挑战,四个重点行业的公司可以通过多种方法将二氧化碳排放量接近零。最有希望的是提高能源效率,加热电气化,使用以零碳电力作为原料或燃料制成的氢气,使用生物质作为原料或燃料,碳捕集与封存(CCS)或使用(CCU)。脱碳方案的最佳组合因装置而异,即使在同一区域内也是如此,因为当地因素决定哪些是最实用或最经济的。公司必须通过仔细检查这些因素,在特定地点评估其选择。

The most important factors are the availability and cost of low-carbon energy sources—specifically, zero-carbon renewable electricity and sustainably produced biomass. Access to storage capacity for captured CO2, along with public and regulatory support for carbon storage, will affect the possibility of implementing CCS. The regional-growth outlook for the four focus sectors matters, too, because certain decarbonization options are cost effective for existing (brownfield) industrial facilities while others are more economical for newly built (greenfield) facilities.

最重要的因素是低碳能源的可用性和成本 - 特别是零碳可再生电力和可持续生产的生物质。获取二氧化碳捕集的存储容量以及碳储存的公共和监管支持将影响实施CCS的可能性。四个重点部门的区域增长前景也很重要,因为某些脱碳方案对现有(棕色地带)工业设施具有成本效益,而另一些对新建(绿地)设施更为经济。

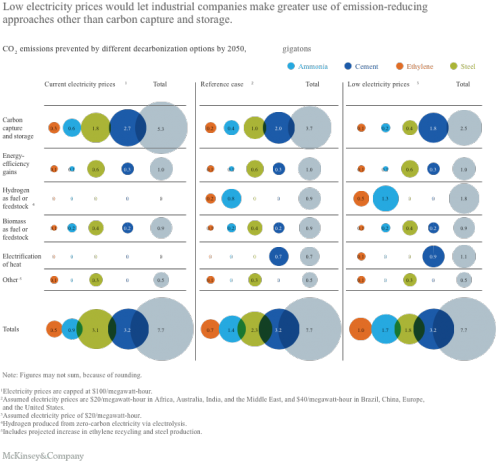

The following observations, which reflect current commodity prices and technologies, can help industrial companies focus their efforts (Exhibit 2):

以下观察结果反映了当前的商品价格和技术,可以帮助工业企业集中精力(图表2):

Exhibit 2

- 1. Improving energy efficiency is a cost-effective way to lower CO2 emissions by 15 to 20 percent. That would be a good start, but it is far from enough to achieve the deep GHG reductions that many Paris Agreement pledges call for. And because energy-efficiency improvements can have longer financial-payback times than companies will accept, many businesses will not pursue these improvements to the extent required for 15 to 20 percent emission cuts.

提高能源效率是将二氧化碳排放量降低15%至20%的经济有效方法。 这将是一个良好的开端,但远远不足以实现许多“巴黎协定”承诺要求的温室气体减排量。 而且,由于能源效率的提高可能比公司接受的财务回报时间更长,因此许多企业不会在减排15%至20%的范围内追求这些改进。

- 2. Where carbon-storage sites are available, CCS is the lowest-cost decarbonization option at current commodity prices. It is also the only technology that can fully abate process-related CO2 emissions from cement production. Otherwise, CCS is still expensive, at least for now. Further innovation could make other decarbonization options, such as electricity-powered production, cost competitive.

在有碳储存地点的地方,CCS是目前商品价格最低成本的脱碳选择。 它也是唯一能够完全减少水泥生产中与工艺相关的二氧化碳排放的技术。 否则,CCS仍然很昂贵,至少目前如此。 进一步的创新可以使其他脱碳选择,如电力生产,成本具有竞争力。

- 3. When the wholesale price of zero-carbon electricity is no greater than $50 per megawatt-hour, using electricity to produce either heat or hydrogen would be more economical than CCS in many situations. (Electricity prices at this level have been attained in some places and will probably become more widespread.) As noted above, a variety of circumstances will dictate the price at which zero-carbon electricity becomes the more cost-effective decarbonization option. Below $35 per megawatt-hour, for example, it’s cheaper to use hydrogen for fuel at newly built ammonia or steel plants designed around hydrogen than to use CCS.

当零碳电力的批发价格不超过每兆瓦时50美元时,在许多情况下使用电力生产热量或氢气比CCS更经济。 (在某些地方已达到这一水平的电价,并且可能会变得更加普遍。)如上所述,各种情况将决定零碳电力成为更具成本效益的脱碳选择的价格。例如,每兆瓦时小于35美元,在氢气设计的新建氨水或钢铁厂使用氢气比使用CCS更便宜。

- 4. Switching to biomass as a fuel or feedstock is financially attractive at cement factories and newly built steel plants because mature technologies are available for biomass in these settings. Biomass can also replace fossil-fuel feedstocks for ethylene and ammonia production. Although this approach costs more than electrification or hydrogen usage, it abates emissions from both the production process and from end-of-life product disposal (for example, incinerating plastic made from ethylene). One big challenge: sustainably produced biomass is scarce at the global level, though it is abundant in some regions.

在水泥厂和新建钢厂中转换为生物质作为燃料或原料在经济上具有吸引力,因为在这些环境中可以获得成熟的生物质技术。生物质还可以替代乙烯和氨生产的化石燃料原料。虽然这种方法的成本高于电气化或氢气使用,但它减少了生产过程和报废产品处理(例如,焚烧乙烯制塑料)的排放。一个巨大挑战:可持续生产的生物质在全球范围内很少,尽管在某些地区很多。

Investment pathways toward low-carbon industry

低碳产业的投资途径

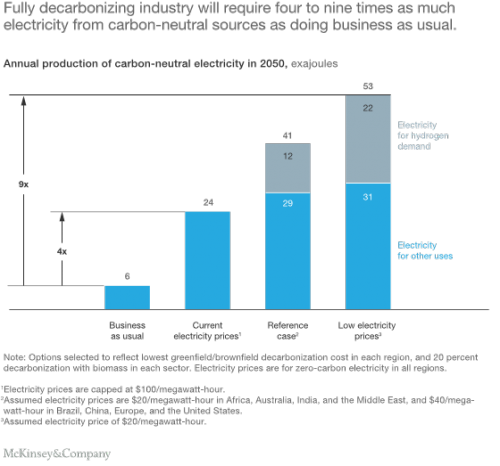

Almost irrespective of which decarbonization option a company chooses—except for energy-efficiency improvements—decarbonization leads to an increase in demand for electricity. To decarbonize, the four focus sectors will need a reliable, low-cost supply of approximately 25 to 55 exajoules of zero-carbon electricity per year—about four to nine times the amount they would need in the absence of any special effort to reduce CO2 emissions (Exhibit 3). Achieving such an increase in the supply of zero-carbon electricity would require a significant and costly transformation of the energy system. The industrial sector can help lower the cost of this change in certain ways, such as providing grid-balancing services.

几乎不管公司选择哪种脱碳方案 - 除了能效改进 - 脱碳导致电力需求增加。 为了实现脱碳,四个重点行业将需要一个可靠,低成本的供应,每年大约25至55埃焦耳的零碳电力 - 在没有任何减少二氧化碳的特殊努力的情况下,需要大约四到九倍的数量。 排放(图表3)。 实现零碳电力供应的这种增加将需要能源系统的显着且昂贵的转变。 工业部门可以通过某些方式帮助降低这种变化的成本,例如提供电网平衡服务。

Exhibit 3

Even so, the investments needed to fully decarbonize the ammonia, cement, ethylene, and steel sectors will be substantial: $11 trillion to $21 trillion through 2050—0.4 to 0.8 percent of global GDP—depending on the price of zero-carbon electricity. Operating expenses constitute 50 to 60 percent of the cost, and capital expenditures, mainly for decarbonizing the cement sector, make up the rest.

即便如此,对氨,水泥,乙烯和钢铁行业进行全面脱碳所需的投资将是巨大的:从全球GDP的2050-0.4%到0.8%的11万亿美元到21万亿美元 - 取决于零碳电力的价格。 经营费用占成本的50%至60%,主要用于水泥行业脱碳的资本支出占其余部分。

Pathways and obstacles to a low-carbon economy

低碳经济的途径和障碍

Achieving the dual transformation of the energy and industrial sectors will require coordinated efforts across the economy. Governments can develop road maps for industrial decarbonization on the local and regional levels to create a more certain outlook for industrial and power companies and unlock investments with longer payback times. Governments can also adjust regulations and incentives to support decarbonization—for example, encouraging investment in renewable-generation capacity by altering the financial requirements on utilities and other companies involved in generating and distributing energy.

实现能源和工业部门的双重转型需要整个经济的协调努力。政府可以制定地方和区域层面的工业脱碳路线图,为工业和电力公司创造更加确定的前景,并以更长的投资回收期解锁投资。政府还可以调整支持脱碳的法规和激励措施 - 例如,通过改变公用事业和其他参与能源生产和分配的公司的财务需求,鼓励对可再生能源发电能力的投资。

Industrial companies should prepare for decarbonization by conducting a detailed review of all their facilities and looking at the availability of low-cost electricity, hydrogen, biomass, and carbon-storage capacity. They can also engage other stakeholders in finding opportunities for collaboration: co-investing in a shared carbon-storage infrastructure, for example, or supporting research and development for promising decarbonization technologies.

工业企业应通过对其所有设施进行详细审查并考虑低成本电力,氢气,生物质和碳储存能力的可用性来为脱碳做好准备。他们还可以让其他利益相关者参与寻找合作机会:共同投资共享碳储存基础设施,或支持有前景的脱碳技术的研发。

All in all, industrial companies can drastically lower their carbon emissions, but only by collaborating with other stakeholders. Joint planning and timely action can accelerate the development of low-carbon technologies for industry and help to coordinate the dual transformation of the energy and industrial sectors. For industrial companies and other organizations, the time to begin the transition is now.

总而言之,工业企业可以大幅降低碳排放量,但只能与其他利益相关方合作。联合规划和及时行动可以加速工业低碳技术的发展,有助于协调能源和工业部门的双重转型。对于工业公司和其他组织,现在是开始转型的时候了。